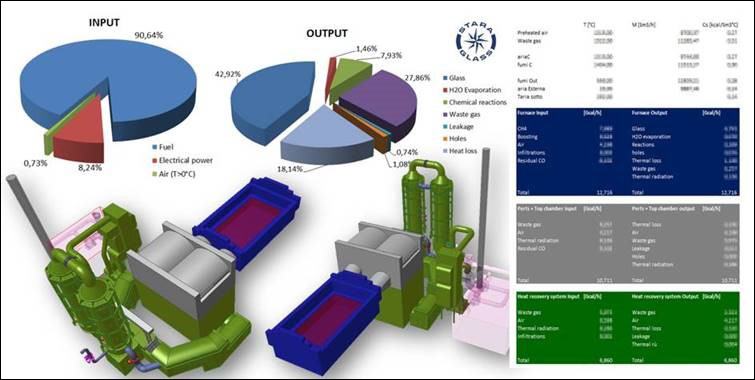

The furnace condition

Heat balance is an “evidence based“ assessment, carried out by our high-level technicians, that depicts the “bill of health” of the furnace while in operation. SGRPRO, during the heat balance exercise, are already able to provide the customer with useful suggestions on how to improve the furnace efficiency.

- Check the general plant conditions.

- Maximize performance, in terms of consumption and quality.

- Identify strength and weakness of the furnace, in order to solve present problems and optimize next campaign design.

- Verify the precision of measure instruments installed on the plant.